There are many good reasons for building your offshore container from the beginning precisely as you would like it designed.

There are many good reasons for building your offshore container from the beginning precisely as you would like it designed.

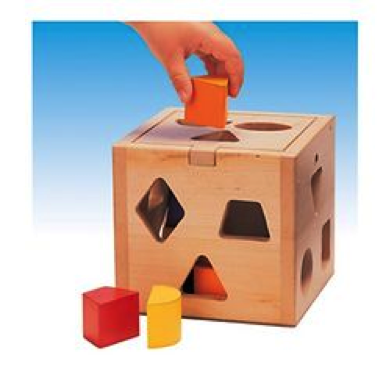

If you had a shape sorter you would never try to squeeze a square block into the triangular hole… No, you would find the square hole and place your block where it fits. Then why is it so often seen that if a containerized plant or workshop is needed offshore, then one buys a new standard offshore container and then spends time and money on welding, cutting and removing portions of the container, so that the plant or workshop fits. Would it not be a good idea to get all the pieces to fit in the first place and build the right container solution from the beginning?

3 good reasons to build your container after your design from scratch

– You start by building a perfect solution, so the strength of your container is adapted to your product and paint is applied when container is completely finished. Thus ensuring the optimal fit.

– It requires very little work from you. We are here to easily and quickly get drawings and specifications in place.

– You save unnecessary transport costs, time and waste by us having an optimal set-up with factories and with partners in Denmark.

Use us as a partner for the design. We have already made custom-built containers to customers, we know the international offshore standards, and we know what can and can not be done.

There is lot of possibilities

Take a look here. These are just a few of the possibilities that exist. If you have questions regarding the special design of offshore containers you can always contact us here at Specialcontainer.dk.

Sometimes you might need short delivery time for a standard or customized container. Right now we have new 6 ‘, 8’, 10 ‘, 20′, in Denmark, which are available to you within a day or two, and which we can get customized through our network of contractors. We will also soon have new 10′ and 20’ HC available.